WELL......things aren't quite as good as I first thought....

I took the front cover off the deck (after removing it from the wood case) so I could clean/check/lubricate the parts.

In the center of the picture is an aluminum pulley, between the two tape spindles. Look closely, and you'll see a black strap-shaped thing laying there. It's the main drive belt, and was in three pieces.

OOOPS! Well, at least the seller gave me two sets of spare belts, one for the main drive, and a smaller one for the tape counter. So, that means the rear panel has to come off, and the deck pulled from the wood case.

Looks clean inside.

And after some fits and starts determining which screws to remove per the manual, I had the transport mechanism out of the case.

The entire capstan assembly has to be removed from the chassis to replace the belt; no way around it, as per several forums and YouTube videos. You have to remove four large screws (here we go again, which four screws?) the get the capstan assembly loose enough to snake the belt in there, and get it around the large driven pulley.

About this time I printed out the entire service manual and put it in a binder, as running back and forth between the garage and PC isn't conducive to efficient use of time.

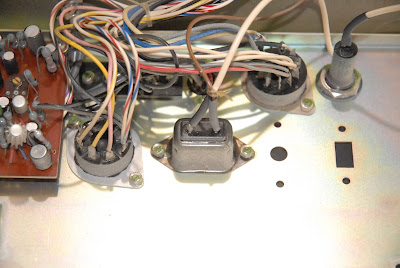

While the manual was printing, I dropped the rear chassis plate so I could get at the four screws.

Two things grabbed my attention. Since I'm going to have to flip the chassis over numerous times to get the screws out and swap the belt, I began wondering about some way to strap the rear plate to the main chassis so I wouldn't have to put undue flexing and strain on a 50~60 year old wiring harness, generally NOT a good idea.

Lo and behold, TEAC thought about that, and made provisions to use two of the rear panel screws to secure the rear panel to the main chassis!

See the screw with the Tinnerman nut and the U-Slots in the panel?

Yep, they put them there to hold the panel while you work on the chassis.

Now the rear panel is held tight allowing you to flip the chassis over. Thank you, TEAC!

One other item I addressed "While I was In There" (yep, sounds like "Mission Creep") was to replace the ancient two-wire AC socket with a modern three-wire socket that takes a standard power cord.

Old:

New:

And there was even a perfectly placed terminal strip, with an unused ground lug, bolted solidly to the chassis I was able to use for the ground wire.

I also visually checked all of the electrolytic capacitors for leakages, bulging, and failing seals, and they all look "Good to Go". Since this was made when Japanese capacitors were very high quality, I don't have any issues with leaving them in place. So tonight's work consisted of getting the new capstan and tape counter belts installed, lubing a couple of points that needed it, making sure all the solenoid-driven linkages were smooth, free to move, and not binding, and doing a few mechanical adjustments that just didn't "feel right" to me. Sure enough, the service manual confirmed they were out-of-spec, and gave the measurement numbers and procedure. Tomorrow will be an inspect my own work day, and putting the deck back in the case after I clean the gorgeous wood case it's in, and do a once-over on all the visible parts again.

I would have had this finished by now, but Sunday is the day TLG comes by, so that takes precedence here! He's excited about the new stereo in the workshop, but doesn't know what a tape recorder is.....yet. He starts dancing around in the garage and yelling "ROCK AND ROLL!!" whenever a good rock song comes on, so I think he might be impressed to hear a good stereo setup, especially if I play Blue Oyster Cult "Godzilla". When I do that, he starts doing his Dinosaur Dance, and he knows all the lyrics to the song.

And I really need some better speakers in the garage. The $30/pair Pyle speakers just don't make enough volume out in the garage. Need some better air pumps! I'll have to see what they have at the Bizarre Bazaar that's suitable for "Garage Speakers".

The nuts and bolts work of electronics repair is the only electronics repair that I'm capable of doing.

ReplyDeleteI remember visiting a high school friend on his submarine after bumping into him at the Rota Exchange.

There was a reel to reel tape player much like yours and my buddy said they used it to record broadcast radio for the entire time they were inport.

That way there was something to listen to during patrols.

So far this is just a "Nuts and Bolts" type of repair. I still have to change the tape counter drive belt, and put a bit of DeoxIT in the level control pots, and recheck my work, but I should have it finished today.

Delete