As I mentioned yesterday, the first electrical issue I ran across in rebuilding this deck is that it kept dropping out of Play. A bit of sleuthing around revealed that the Reel Motor was the most likely culprit, so in I went.

These pictures aren't mine. I borrowed them from the HiFi Haven website, where member Pustelniakr was kind enough to document the entire procedure.

It's a small DC motor, with a couple of centrifugal switches on it to

control the speed. In "Play", it runs at a reduced voltage, regulated speed, and in "Fast

Forward" and "Rewind" it gets full voltage and really spins.

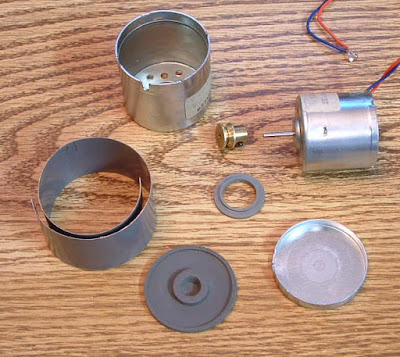

And it's a "can motor" inside another can!

The coiled strip of metal on the right is a strip of Mu-Metal for magnetic shielding. Even though the permanent magnet inside the motor can on the right is pretty well shielded, Pioneer used to the "belt and suspenders" approach to really keep the magnetic flux bottled up inside the cans so it couldn't degauss the tape as it was in the deck.

The two round grey things are silicone rubber shock mounts that suspend the motor can inside the shield can. It mechanically isolates the motor from the chassis, so vibrations from one don't upset the other.

The armature assembly out of the case after prying open some crimps:

The small toroid inductor is in series with the DC Voltgae coming in. There's a capacitor to ground on the other brush, and they form a filter to keep the electrical noise from the brushes on the commutator from getting into the other electronics.

Brushes:

My brush plate wasn't this dirty, but I cleaned it very well anyway. The brushes themselves appear to be a carbon/copper composition, they're brazed to the little arms that hold them, and showed practically ZERO wear when examined under 20X magnification.

This is the entire armature for the motor. The centrifugal switches are on the left, and the commutator on the right:

Yep, the commutator is filthy, grooved, and not as "flat" as it should be. This is the same as on a starter motor for a car. That operation is called "cutting the comm", "turning the comm", or other phases I forget. For a starter motor you chuck the armature into an "Armature Lathe", and use a cutter to refinish the surface.

Before:

This is a whole bunch more delicate, so I chucked the motor shaft into my cordless Dremel tool, ran it at the lowest speed possible, and used a strip of 2000 grit sanding film to clean it up.

Again, these aren't my pictures, but this is essentially what I did:

After, but mine has a more uniform nice, bright copper look on all the surfaces:

These are the contacts for the two centrifugal switches. Just clean them gently with a strip of paper, and DO NOT adjust them, or you'll turn the motor into a paperweight:

SO....after spending a week diagnosing this, then taking the transport apart again to pull the motor, rebuilding the motor and reinstalling it, and finally putting the entire transport back together The Verdict Is.....Problem Resolved!

It now stays in play, the voltages across the motor are by-the-book, and Fast Forward/Rewind blast along MUCH faster than they did before.

Tomorrow's installment will be "Those Pesky Pinch Rollers, and What to Do About Them".