Was 99% what I expected it to be. Get checked in, change into some scrubs, lay down on the table, get the "Radio Frequency Coil Assembly" (30~50MHz) strapped on, and the get inserted into the maws of The Mighty MAGNETOM!

I had foam earplugs in, a big rubber bulb "Panic Button", and a "Pneumatic" headset on to listen to music while the big machine cranked through it's routine. The headset was similar to what I'd seen on commercial airliners years ago, where a little "speaker" in the armrest was sealed to a plastic port that your "headphones" plugged into. The "headphones" were just plastic tubing that carried the sound from the armrest mounted speaker to your ears. Very clever, lightweight, and CHEAP. And they consist of nothing conductive, or magnetic, and important consideration when the person wearing them is enclosed by a very powerful, pulsed magnetic field. No long run of wire that could get a voltage induced in it. Same with the squeeze-bulb Panic Button.

Look, Ma...NO Wires!

I didn't think it was all that loud, but then my hearing is shot, I knew what it was doing, and loud "industrial" noises like that don't usually faze me. And seeing as both ends are open, I don't get the "claustrophobic" part of it, but I guess it could be pretty intimidating.

The worst part? It was cold in the room, followed by what they called "Classic Rock" in my music selection wasn't what I'd call Classic Rock. Yeah, I know, a real "First World" problem. The Tech who ran the test gave me a heated blanket, better than 1st class on an overseas flight, and that kept me nice and snug.

Now in a Past Life, I was a Components Engineer for a company called "Searle Diagnostics", formerly "Nuclear Chicago", and they produced Radiological Imaging Units (aka "Gamma Cameras"), and Radiological Immunoassay Units for what used to be called "Nuclear Chemistry" back in the day. And one of our departments was building their first "CAT Scanner", a soon-to-be product line.

Alas for them, they hit some development snags, GE was first-to-market, and the project folded. Searle wound up selling that operation lock-stock-and-barrel to Siemens, who rechristened it "Siemens Gammasonics", the new name indicating they were now into Ultrasound as well as staying in the Nuclear Medicine business.

Where's this going? The mighty MAGNETOM was made by Siemens, and would be the great-great-great-grandchild of the things I watched being built for the first time.

It's kind of like being a Technician for Marconi, and living long enough to see communications satellites in daily use for mundane things.

Or going from points-and-coil ignition and carburetors to electronic sequential fuel injection and coil-on-plug ignition.

We truly live in amazing times.

Admiral Yamamoto infamously said "You cannot invade the mainland United States. There would be a man with a rifle behind every blade of grass."

And so it should be, a nation of riflemen....

Saturday, February 15, 2020

Monday, February 10, 2020

Sea Launch to Relocate to Eastern Russia in February, 2020

It's official.

The ship's will be leaving for Slavyenka on February 22nd.

And I just heard that they're going to tow the Launch Platform.

Through the North Pacific.

In the winter.

Gee, what could go wrong with that?

More (minimal) details here.

Turns out the Launch Platform will be towed out to sea about 9 miles, and then loaded on to a carrier ship (something like the Mighty Servant), and then be transported to it's new port.

The ship's will be leaving for Slavyenka on February 22nd.

More (minimal) details here.

Turns out the Launch Platform will be towed out to sea about 9 miles, and then loaded on to a carrier ship (something like the Mighty Servant), and then be transported to it's new port.

Sunday, February 9, 2020

Hip Problems, X-Rays, MRI's and Other Stuff

I'll be the first to admit I haven't been running at 100% the last week or so. My right hip has flared up, and it hasn't been much "fun".

So, I went to the Doctor's office last Tuesday and she checked things out, asked a bunch of questions, did the rotation/extension/flexion stuff, and sent me down to the walk-in clinic for X-Rays of the hip and lumbar region. The results indicate some arthritis in the hip (no surprise there), and some minor "Bone Spurs" in the lumbar region.

As usual, the X-Rays were just to check that the basic structure is OK, and I'm going in for an MRI on Friday afternoon. And of course, they're going to run me through the Physical Therapy routine, although every time I've had PT it hasn't done much.

In the meantime, it's 400mg of Ibuprofen every 4~6 hours, along with half a Tramadol tablet. The Ibuprofen helps knock down any inflamation, and Tramadol relieves most of the pain. A full Tramadol knocks the pain to zero, but also knocks me into an alternative reality for a couple of hours.

No thanks, I'm wacky enough as is!

And what happened to the spell check function on Blogger? Mine's gone AWOL.

So, I went to the Doctor's office last Tuesday and she checked things out, asked a bunch of questions, did the rotation/extension/flexion stuff, and sent me down to the walk-in clinic for X-Rays of the hip and lumbar region. The results indicate some arthritis in the hip (no surprise there), and some minor "Bone Spurs" in the lumbar region.

As usual, the X-Rays were just to check that the basic structure is OK, and I'm going in for an MRI on Friday afternoon. And of course, they're going to run me through the Physical Therapy routine, although every time I've had PT it hasn't done much.

In the meantime, it's 400mg of Ibuprofen every 4~6 hours, along with half a Tramadol tablet. The Ibuprofen helps knock down any inflamation, and Tramadol relieves most of the pain. A full Tramadol knocks the pain to zero, but also knocks me into an alternative reality for a couple of hours.

No thanks, I'm wacky enough as is!

And what happened to the spell check function on Blogger? Mine's gone AWOL.

Tuesday, February 4, 2020

SOTU

We didn't watch it tonight because we were busy watching something else.

Cold, clear night, so we made a fire, had macaroni and cheese along with some lentil soup, and played with "Kinetic Sand" and one of my favorites, Play-Doh, seen here In Action! Yes, Pebbles was down in the den with us, just slightly out-of-frame to the right, always watching TLG, and in Condition Yellow. Woe betide somebody who makes a threatening move while she's On Duty. I'm sure she'd go full berserker mode to defend us.

Anyway, from what I've read, "Madame" Speaker displayed some interesting behavior that would have gotten her dragged out back and disappeared in a lot of places. I'm sure I'll get to see replays, but for Real Time viewing, this was far more important.

Cold, clear night, so we made a fire, had macaroni and cheese along with some lentil soup, and played with "Kinetic Sand" and one of my favorites, Play-Doh, seen here In Action! Yes, Pebbles was down in the den with us, just slightly out-of-frame to the right, always watching TLG, and in Condition Yellow. Woe betide somebody who makes a threatening move while she's On Duty. I'm sure she'd go full berserker mode to defend us.

Anyway, from what I've read, "Madame" Speaker displayed some interesting behavior that would have gotten her dragged out back and disappeared in a lot of places. I'm sure I'll get to see replays, but for Real Time viewing, this was far more important.

Sunday, February 2, 2020

The Warm Before The Storm.....

Yow....it's Seventy-Two Degrees here today! Strong winds from the SW, averaging 10MPH with gusts to around 30MPH. It's a beautiful day, and even with the wind, it feels warm. Pebbles did her first session of roll-around-in-the-yard for the year, coming back in the house pretty well covered in dead grass and leaves! Took a few minutes to brush her off, but it was fun watching her enjoy this little bit of "Spring Preview". And she even ignored all the squirrels running along the top of the fence between their tree, and the front of our house where the maple tree still has a bountiful crop of seeds. Guess the squirrels are stocking up for the next few days.

BUT.....the temps are going to start dropping tonight, and rain turning to snow is expected on Monday with a high of 24*. Snow accumulation of 1"~3" is expected during the day, with another 2"~4" predicted overnight.

Monday night will drop into the single-digits, and Tuesday night is expected to get down to about -2*.

TLG will be staying here Tuesday/Wednesday, so I forecast lots of game-playing, R/C Car Action down in the den, and a nice fire going later in the day. I have a bunch of crab apple wood that came from some large branches that broke off the tree last year, and they dried out very nicely over the summer before I cut them up and stacked them. I don't know if crab apple wood burns well, but I'll try some small pieces to see how it works.

Been kind of off-line the last few days. Having some problems with my right hip acting up, and I'm not getting much sleep at night. So, I'll call my Doctor's office tomorrow and see if she has time to see me. Otherwise, I'll be headed down to the urgent care clinic. Something's not quite right, and I need to tend to it.

Enjoy the rest of your weekend, and no, I'm not watching the Stupid Bowl.....

BUT.....the temps are going to start dropping tonight, and rain turning to snow is expected on Monday with a high of 24*. Snow accumulation of 1"~3" is expected during the day, with another 2"~4" predicted overnight.

Monday night will drop into the single-digits, and Tuesday night is expected to get down to about -2*.

TLG will be staying here Tuesday/Wednesday, so I forecast lots of game-playing, R/C Car Action down in the den, and a nice fire going later in the day. I have a bunch of crab apple wood that came from some large branches that broke off the tree last year, and they dried out very nicely over the summer before I cut them up and stacked them. I don't know if crab apple wood burns well, but I'll try some small pieces to see how it works.

Been kind of off-line the last few days. Having some problems with my right hip acting up, and I'm not getting much sleep at night. So, I'll call my Doctor's office tomorrow and see if she has time to see me. Otherwise, I'll be headed down to the urgent care clinic. Something's not quite right, and I need to tend to it.

Enjoy the rest of your weekend, and no, I'm not watching the Stupid Bowl.....

Monday, January 27, 2020

Valco Supro Rebuild Completed

And it was a nice little side project that I've been meaning to get completed since I found it in the garage in Long Beach.

On the bench making the final voltage measurements.

The first thing I did was to bring it up on my Variac with the tubes pulled, measuring the input voltage and current draw. Since this had been stored for many years under less than ideal conditions, I had some concerns that the power transformer might be bad. It came up fine, and the filament voltage and high voltage measurements went as expected.

One interesting observation I made was that this was designed for 110VAC voltage. The nominal filament voltage for the rectifier tube is 5 Volts, provided by a separate secondary winding, and it measured 5 Volts with 110VAC applied to the primary. At today's nominal 120VAC, the filament voltage measured 5.65 Volts. The other filament winding for the 6 Volt tubes measured 6.7 Volts. The increased filament voltage will definitely have a negative effect on the life of the tubes, but there's not much you can easily do about it, so you just have to accept it. I've read about this in "Electric Radio" magazine, a magazine devoted to "Boat Anchor" (tube type) Amateur Radio gear, and read about it on other equipment restoration websites, so I was well aware of it.

Top of the chassis after testing completed. I didn't check to see what size tape I had in my "P-Touch" label printer so the tube type labels are a bit bigger than I would prefer.

And back in the cabinet.

So how does it sound? About what I expected from an amplifier of this design and construction. Has a bit of hum when the volume is wide open, and it's not as loud as I expected, but overall it has a nice "warm" mellow sound. All I had to plug into it was an Audio-Technica ATR30 500 Ohm dynamic microphone, which is probably not optimum for this amp, but ya' gotta' work with what ya' got sometimes.

I have no idea what I'm going to do with this little amp. I don't play, and I don't think any of The Clan does, either. Oh, well, back of the closet, I guess.

Next up will be the Arcuino-based lightning detector, something I need to get finished before Spring.

On the bench making the final voltage measurements.

The first thing I did was to bring it up on my Variac with the tubes pulled, measuring the input voltage and current draw. Since this had been stored for many years under less than ideal conditions, I had some concerns that the power transformer might be bad. It came up fine, and the filament voltage and high voltage measurements went as expected.

One interesting observation I made was that this was designed for 110VAC voltage. The nominal filament voltage for the rectifier tube is 5 Volts, provided by a separate secondary winding, and it measured 5 Volts with 110VAC applied to the primary. At today's nominal 120VAC, the filament voltage measured 5.65 Volts. The other filament winding for the 6 Volt tubes measured 6.7 Volts. The increased filament voltage will definitely have a negative effect on the life of the tubes, but there's not much you can easily do about it, so you just have to accept it. I've read about this in "Electric Radio" magazine, a magazine devoted to "Boat Anchor" (tube type) Amateur Radio gear, and read about it on other equipment restoration websites, so I was well aware of it.

Top of the chassis after testing completed. I didn't check to see what size tape I had in my "P-Touch" label printer so the tube type labels are a bit bigger than I would prefer.

And back in the cabinet.

So how does it sound? About what I expected from an amplifier of this design and construction. Has a bit of hum when the volume is wide open, and it's not as loud as I expected, but overall it has a nice "warm" mellow sound. All I had to plug into it was an Audio-Technica ATR30 500 Ohm dynamic microphone, which is probably not optimum for this amp, but ya' gotta' work with what ya' got sometimes.

I have no idea what I'm going to do with this little amp. I don't play, and I don't think any of The Clan does, either. Oh, well, back of the closet, I guess.

Next up will be the Arcuino-based lightning detector, something I need to get finished before Spring.

Saturday, January 25, 2020

Some Giggles For You.....

Don't know if I've ever done a strictly humor post, although sometimes my writing's a bad joke.

Anyway......Enjoy!

That's All, Folks!

Anyway......Enjoy!

That's All, Folks!

Friday, January 24, 2020

Valco Supro Update

And yes, the bread is just as good the "next day" as it was out of the oven, but alas.....the crust loses it's crispy crunchiness within 12 hours, even when bagged. If I left it unbagged it would become construction material within a few days.

It's DRY here!

So I've also been tinkering at least 30~45 minutes a day on the Valco. I had a 20uF/450V cap for the first filter, but didn't have any 10uF/450V caps for the second and third filters, so I put off rebuilding the power supply section until I had the capacitors "in stock", and they arrived yesterday.

Here's the power supply filter section rebuilt with all new parts.

And the complete chassis.

I'll bench test it before I put it back in the cabinet, as I want to record all the voltages. I'll bring it up slow on my big Variac, and monitor the input voltage and current without the tubes in it This will let me record the No Load voltages that the transformer puts out, and measure the excitation current, telling me the "health" of the Power Transformer.

I cleaned the case as well as I could, which really isn't very well, and glued down as much of the loose covering material as I could. The "Tolex" vinyl covering is pretty shot on the top, with much evidence of the amp being used as a small table. I guess the ring-shaped watermarks and "cigarette" burns are just part of this little amp's history.

It does look much better with the cleaned, reversed piece of grill cloth in there!

The hardware on the new leather handle is almost too shiny. I would have just changed the handle part, but the OEM hardware was riveted in. There was no way I could have removed it without damaging something, so I took my Dremel and used a cut-off wheel to slice off the rivet heads. You have to remove the handle to replace the strap because there's little pins coming down from the hardware, through the slots in the strap, and then down into the wood, to prevent the strap from pulling out.

And the replacement speaker dropped right in, as hoped.

Now I'm scratching my head trying to decide if I should rebuild the missing back plate that looks like this.

I can easily get and cut a nice piece of wood to fit there, but I don't have a router to do the nice edge. I wouldn't cover it, just stain it dark, and maybe "age" it a bit and bang it around a bit so it looks like the rest of the amp.....

On the model car front, I had an "Epiphany" the other day regarding the motive system. Turns they use a "Six Step Inverter" to power the little brushless motors with. In finding and reading the datasheets from the manufacturers who produce the controller chips, I went over the waveforms fed to the motor, and son-of-a-gun, they're identical to the waveforms of the equipment I used to design for McGraw-Edison back in Illinois.

..........grok..........

So now I'm sketching up some diagrams and drawings for a small dynamometer to test and measure these things with. I've done it before, but the smallest motors we worked with were around 50HP, going on up to 450HP, which was the largest off-the-shelf 480V three-phase motor you could buy at the time.

And it looks like a lot of the specs on this "Hobby Grade" stuff are inflated enough to send my bogosity meter towards the top end. Reminds me of the Wild West days of home audio when outrageous claims for the output power of home stereos were the norm.......

It's DRY here!

So I've also been tinkering at least 30~45 minutes a day on the Valco. I had a 20uF/450V cap for the first filter, but didn't have any 10uF/450V caps for the second and third filters, so I put off rebuilding the power supply section until I had the capacitors "in stock", and they arrived yesterday.

Here's the power supply filter section rebuilt with all new parts.

And the complete chassis.

I'll bench test it before I put it back in the cabinet, as I want to record all the voltages. I'll bring it up slow on my big Variac, and monitor the input voltage and current without the tubes in it This will let me record the No Load voltages that the transformer puts out, and measure the excitation current, telling me the "health" of the Power Transformer.

I cleaned the case as well as I could, which really isn't very well, and glued down as much of the loose covering material as I could. The "Tolex" vinyl covering is pretty shot on the top, with much evidence of the amp being used as a small table. I guess the ring-shaped watermarks and "cigarette" burns are just part of this little amp's history.

It does look much better with the cleaned, reversed piece of grill cloth in there!

The hardware on the new leather handle is almost too shiny. I would have just changed the handle part, but the OEM hardware was riveted in. There was no way I could have removed it without damaging something, so I took my Dremel and used a cut-off wheel to slice off the rivet heads. You have to remove the handle to replace the strap because there's little pins coming down from the hardware, through the slots in the strap, and then down into the wood, to prevent the strap from pulling out.

And the replacement speaker dropped right in, as hoped.

Now I'm scratching my head trying to decide if I should rebuild the missing back plate that looks like this.

I can easily get and cut a nice piece of wood to fit there, but I don't have a router to do the nice edge. I wouldn't cover it, just stain it dark, and maybe "age" it a bit and bang it around a bit so it looks like the rest of the amp.....

On the model car front, I had an "Epiphany" the other day regarding the motive system. Turns they use a "Six Step Inverter" to power the little brushless motors with. In finding and reading the datasheets from the manufacturers who produce the controller chips, I went over the waveforms fed to the motor, and son-of-a-gun, they're identical to the waveforms of the equipment I used to design for McGraw-Edison back in Illinois.

..........grok..........

So now I'm sketching up some diagrams and drawings for a small dynamometer to test and measure these things with. I've done it before, but the smallest motors we worked with were around 50HP, going on up to 450HP, which was the largest off-the-shelf 480V three-phase motor you could buy at the time.

And it looks like a lot of the specs on this "Hobby Grade" stuff are inflated enough to send my bogosity meter towards the top end. Reminds me of the Wild West days of home audio when outrageous claims for the output power of home stereos were the norm.......

Wednesday, January 22, 2020

Bread.....Epilogue

Was gonna start this earlier today, but TLG was here, and we were reading "Pop-Up" books, much to his delight. He certainly enjoys books, and that's a behavior we definitely encourage. He knows all his colors, most of the ABC's, and can count forwards (and backwards!) from zero to ten.

Yeah, I'm the guilty party for insisting he include zero in his counting. And he learned them backwards hanging around with me doing simulated countdowns. It was a real treat watching his Lightbulb Of Comprehension go on when he realized the numbers were the same, but they meant different things going up and coming down.

Anyway....back to the bread.....

I used my Standard Reference Recipe for this batch, proofed the yeast (a fascinating subject all it's own) while I fluffed and measure out the flour, and just to throw another variable into the mix, I dissolved the salt and sugar into the warm water before I added it to the flour. It just seemed the right thing to do to ensure complete mixing.

The major difference this time is that I baked the loaves in the glass bread "pans" we have. Probably just me, but I always associate the word "pan" with something made of metal, hence the quotes. Guess I should just call them baking dishes....

I won't bore you with the construction details of the latest "Bread Build" since you've seen them all except to say I ran the mixer one notch higher this time. It cut the laboring of the motor down, it really mixed the dough well, and when I carefully looked at the slider control, I realized this was the speed I was supposed to be using per the mixer's manufacturer. Le Sigh.....

And I did NOT "gently slash" the tops of the loaves this time, and they did not deflate on me. I just brushed them with warm water, and popped 'em into the preheated 450* oven for 22 minutes.

And the results?

I stone-cold nailed it.

The front loaf is shiny because SLW slathered it with butter before I could grab my camera.

And FINALLY.......bread with some structure!

It cuts easily and stays together, it's light and airy, a little chewy in a good way, and the crust came out great, but a little thin. So the next time I'll bump the time up to 25 minutes to compensate for it being in a glass dish, which will develop the crust a bit more.

So I'm officially announcing I can bake bread! This bread. With this recipe. At this location. YMMV!

Stay tuned for cinnamon rolls. The flour company website has some "Baker's Tricks" to keep them from getting rock-hard in a day or two, and I'm itchin' for some cinnamon rolls.....

Yeah, I'm the guilty party for insisting he include zero in his counting. And he learned them backwards hanging around with me doing simulated countdowns. It was a real treat watching his Lightbulb Of Comprehension go on when he realized the numbers were the same, but they meant different things going up and coming down.

Anyway....back to the bread.....

I used my Standard Reference Recipe for this batch, proofed the yeast (a fascinating subject all it's own) while I fluffed and measure out the flour, and just to throw another variable into the mix, I dissolved the salt and sugar into the warm water before I added it to the flour. It just seemed the right thing to do to ensure complete mixing.

The major difference this time is that I baked the loaves in the glass bread "pans" we have. Probably just me, but I always associate the word "pan" with something made of metal, hence the quotes. Guess I should just call them baking dishes....

I won't bore you with the construction details of the latest "Bread Build" since you've seen them all except to say I ran the mixer one notch higher this time. It cut the laboring of the motor down, it really mixed the dough well, and when I carefully looked at the slider control, I realized this was the speed I was supposed to be using per the mixer's manufacturer. Le Sigh.....

And I did NOT "gently slash" the tops of the loaves this time, and they did not deflate on me. I just brushed them with warm water, and popped 'em into the preheated 450* oven for 22 minutes.

And the results?

I stone-cold nailed it.

The front loaf is shiny because SLW slathered it with butter before I could grab my camera.

Out of the baking dish the loaves held their shape.

And FINALLY.......bread with some structure!

It cuts easily and stays together, it's light and airy, a little chewy in a good way, and the crust came out great, but a little thin. So the next time I'll bump the time up to 25 minutes to compensate for it being in a glass dish, which will develop the crust a bit more.

So I'm officially announcing I can bake bread! This bread. With this recipe. At this location. YMMV!

Stay tuned for cinnamon rolls. The flour company website has some "Baker's Tricks" to keep them from getting rock-hard in a day or two, and I'm itchin' for some cinnamon rolls.....

Sunday, January 19, 2020

Project Updates

Been keeping busy with all the little projects going on here.

Mounted a terminal strip in the Supro amp so I have some tie points for the new capacitors.

Next time you see the chassis I'll have it finished. I put the refurbished grill cloth back in the case, along with the new speaker and carrying handle, but didn't take any pix.....D'OH!

And I brought all the fiddly bits for my little "Senton" 4x4 truck down to the basement, put them all back where they belonged, and tested it for steering and throttle response while it was sitting on the test stand.

Next up for this little guy is to fit the GoPro mount, and wait for the geese to show up. Should be a real Hoot and a Holler!

I also gathered up the parts I had "in stock" for the "Limitless" Speed Run car. Here's the steering servo installed, and the radio being fitted-up.

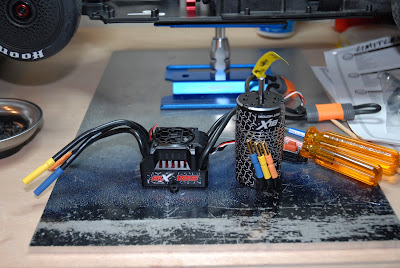

And not wanting to spend $300 on a motor and Electronic Speed Controller ("ESC"), I found a new pull from another Arrma car on eBay, and picked it up for $100. I'm trying to keep the costs on this down, and this motor/ESC pair is plenty good enough for learning how to drive this thing. My fellow Arrm Forum members tell me this "beginner's setup" should be good for 80~85MPH with the stock gearing, and possibly good for ~100MPH with different gearing and some other tuning tweaks.

Electronics package mounted, along with the motor.

After I power the car up the first time and do the initial setup, I'll connect the servo arm, and do the final steering trim. 100MPH = 147 ft/sec, so you really have to have the steering dialed-in, and make some adjustments on the radio to calm it down some. At that speed, a slight twitch on the steering wheel can send you flying off course.

After I'm comfortable driving it in this configuration, I'll upgrade the ESC. The ESC I'm looking at is capable of passing much more current, while running cooler (less loss), and allows more adjustments, one of which is "Braking Strength". You should be able to lock up all four wheels at maximum braking effort (the little truck does this easily), and this ESC can't do that when the vehicle it's in is using the gearing required for high-speed running.

One of the things I have to learn more about are the speed controllers and motors. Way back when, in a different life, I used to design large "Variable Frequency" AC, three-phase motor controls, so I know three-phase power systems fairly well, but that was 40 years ago. One of the differences is that these little brushless DC motors use a permanent magnet rotor, whereas the big motors I used before are your typical three-phase "Squirrel Cage" motors that have aluminum or copper bars making up the rotor. The spinning magnetic field in the stator coils induces currents into the bars, and the rotor gets "dragged" around trying to follow the magnetic field. This causes the rotor to "slip", spinning at a lower speed than the magnetic field rotates at. The permanent magnet rotors don't do this, being pretty much locked into the same rotational speed as the magnetic field.

I've seen schematics of these ESC's on the web, so now I have to go round them up and study them. Time to brush-up on "4 Quadrant Control" again!

Mounted a terminal strip in the Supro amp so I have some tie points for the new capacitors.

Next time you see the chassis I'll have it finished. I put the refurbished grill cloth back in the case, along with the new speaker and carrying handle, but didn't take any pix.....D'OH!

And I brought all the fiddly bits for my little "Senton" 4x4 truck down to the basement, put them all back where they belonged, and tested it for steering and throttle response while it was sitting on the test stand.

Next up for this little guy is to fit the GoPro mount, and wait for the geese to show up. Should be a real Hoot and a Holler!

I also gathered up the parts I had "in stock" for the "Limitless" Speed Run car. Here's the steering servo installed, and the radio being fitted-up.

And not wanting to spend $300 on a motor and Electronic Speed Controller ("ESC"), I found a new pull from another Arrma car on eBay, and picked it up for $100. I'm trying to keep the costs on this down, and this motor/ESC pair is plenty good enough for learning how to drive this thing. My fellow Arrm Forum members tell me this "beginner's setup" should be good for 80~85MPH with the stock gearing, and possibly good for ~100MPH with different gearing and some other tuning tweaks.

Electronics package mounted, along with the motor.

After I power the car up the first time and do the initial setup, I'll connect the servo arm, and do the final steering trim. 100MPH = 147 ft/sec, so you really have to have the steering dialed-in, and make some adjustments on the radio to calm it down some. At that speed, a slight twitch on the steering wheel can send you flying off course.

After I'm comfortable driving it in this configuration, I'll upgrade the ESC. The ESC I'm looking at is capable of passing much more current, while running cooler (less loss), and allows more adjustments, one of which is "Braking Strength". You should be able to lock up all four wheels at maximum braking effort (the little truck does this easily), and this ESC can't do that when the vehicle it's in is using the gearing required for high-speed running.

One of the things I have to learn more about are the speed controllers and motors. Way back when, in a different life, I used to design large "Variable Frequency" AC, three-phase motor controls, so I know three-phase power systems fairly well, but that was 40 years ago. One of the differences is that these little brushless DC motors use a permanent magnet rotor, whereas the big motors I used before are your typical three-phase "Squirrel Cage" motors that have aluminum or copper bars making up the rotor. The spinning magnetic field in the stator coils induces currents into the bars, and the rotor gets "dragged" around trying to follow the magnetic field. This causes the rotor to "slip", spinning at a lower speed than the magnetic field rotates at. The permanent magnet rotors don't do this, being pretty much locked into the same rotational speed as the magnetic field.

I've seen schematics of these ESC's on the web, so now I have to go round them up and study them. Time to brush-up on "4 Quadrant Control" again!

Thursday, January 16, 2020

Subscribe to:

Comments (Atom)

The Winter Wallop Contimues.....

We haven't been clobbered like our friends 'Down South' are getting it. We've had 1~2" of snow and a bunch of cold wea...

%20PiAware%20SkyAware.png)

-

FOURTH time I've written this post. MY Muse has apparently vacated the premises, leaving me too busy doing other things to keep both m...

-

With apologies to The Control Voice.... Yup.....got The Busies the last few weeks. Lots of stuff happening this week, including my Nuclea...