Well, after slotting the screw heads, using my Horror Freight "Electric Flamethrower", and slugging away for 30 minutes, I got the three remaining screws holding the case halves together out.

Some "persuasion" was required...

I tore up two of the three, and had to re-slot them as deep as I could with the Dremel, and along with a generous helping of heat, I got them loose with about five mighty whacks of my BFH hand sledge. I think it rather appropriate it's often called an "Engineer's Hammer".

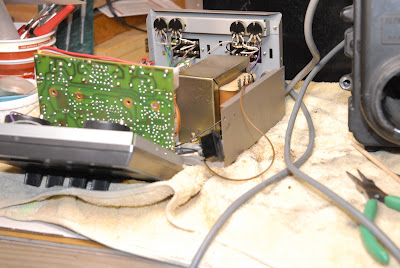

Since I want to set the position to zero degrees elevation, I connected the rotor to one of the control boxes I have with some short jumpers, and tried to turn on the control box.

RATS! The power switch was jammed, so that's getting fixed. The housing for the switch is the black rectangular object.

SO....since I'm now "Waiting On Parts" (again!), I put these aside and opened the case for the azimuth rotor, which I've repaired many of. One thing I've learned (DAMHIK!) is to split and separate the case in a big pan or box to keep the bearings from scattering to the four winds.

Having 80 grease covered bearing balls rolling around loose is not fun. These bearings were packed with a dark gray grease most likely containing Molybdenum Disulfide, an Extreme Pressure additive to the grease.

The gear train in the azimuth unit looks fine, and there's no sign of water ingress, so this unit will get cleaned up, regreased, reassembled, and tested.

So, back to waiting for FedEx/UPS/USPS to get the parts to me so I can finish this up, and ship it out to our blogger friend BillB.

LOL, BFH for the win! :-)

ReplyDeleteHAH! The bigger the better!

Delete