Admiral Yamamoto infamously said "You cannot invade the mainland United States. There would be a man with a rifle behind every blade of grass."

And so it should be, a nation of riflemen....

Saturday, June 29, 2013

Boy Scout Merit Badge Class on the Battleship IOWA

Gonna be a busy day today. I'm helping with the Boy Scout "Radio Merit Badge" class today on the Iowa.

BTW.....we can't call the "U.S.S. Iowa" anymore (sob...sob...) as she's no longer an active ship of the U.S. Navy. We have to refer to the garnd old gal as the "Battleship Iowa".

A small technicality, but an important one none the less.

I'll be in the Comm Center helping the Scouts to get over any On-The-Air shyness (a.k.a. "Mic Fright"), and to make sure nobody does anything STOOOPID while transmitting.

In my experience, the Scouts are all fine young lads who take direction very well, but the FCC requires a "Qualified Control Operator" to be in physical control of the radio gear while unlicensed people use it.

If you know any Scouts, the Radio Merit Badge is one of the lesser-known badges, and a good one to have. I forget how many Merit Badges my son has, but his sash is pretty full.

Time to hit the shower, get dresses, gather up all my materials, and head on down to the Iowa.

See you all later.....

Wednesday, June 26, 2013

Tuesday, June 25, 2013

Field Day AAR

Well, we've had better Field Days, but nobody got hurt, the food was acceptable, the weather was great, and we all had a good time.

On the flip side, due to a solar event a few days previous, propagation was downright stinky on Saturday, making things pretty dull for the guys on HF ("Shortwave").

And try as we could, we just couldn't chase Murphy away this year.

My son forgot we use Friday as a set up day, and didn't take vacation, so I got nothing done at the site on my own station.

Then he upgraded the OS in his iPhone, which nuked his address book, and lost the GPS location of my house.

He got lost, had to call me, and got here 90 minutes late, putting us waaaay off schedule for this year.

Meanwhile, back at the site....

One guy had the lifting cable in his crank-up tower snap when the tower was about 24" up from the bottom, a very good time to have it break. The antenna doesn't drop too far, and nothing was damaged.

The antenna for that station wound up being about 15~18 feet above ground, which really put a dent in how well it worked.

The next station somehow managed to kill his radio, a Kenwood TS-2000 a normally reliable radio. We got him on a spare radio one of the other guys had, at which point he started wondering about his antenna working correctly.

Considering that this particular antenna gets mediocre reviews on eHam, we erected a telescopic mast, and hung a dipole on it.

And I had some really weird "Reverse Desense" problems that I never could overcome, but I think I know what it might be. I swapped out my filters and preamps (the most likely culprits) with no effect, so I just stuck to FO-29 for the weekend.

I "only" made 22 contacts, about half of what I normally do.

And my Azimuth rotor "broke" (I think) on the ride home. It now freewheels when it should be very hard to turn by hand, so I have to look in to what happened there. I transported the mount, rotors, and antennas fully assembled, and I think I shook something a wee bit too hard on the ride back home.

And I forgot my camera, BOTH days!

Only the guys running the CW station got through the whole weekend without a single problem.

Must have been all the garlic they hung around their trailer......

On the flip side, due to a solar event a few days previous, propagation was downright stinky on Saturday, making things pretty dull for the guys on HF ("Shortwave").

And try as we could, we just couldn't chase Murphy away this year.

My son forgot we use Friday as a set up day, and didn't take vacation, so I got nothing done at the site on my own station.

Then he upgraded the OS in his iPhone, which nuked his address book, and lost the GPS location of my house.

He got lost, had to call me, and got here 90 minutes late, putting us waaaay off schedule for this year.

Meanwhile, back at the site....

One guy had the lifting cable in his crank-up tower snap when the tower was about 24" up from the bottom, a very good time to have it break. The antenna doesn't drop too far, and nothing was damaged.

The antenna for that station wound up being about 15~18 feet above ground, which really put a dent in how well it worked.

The next station somehow managed to kill his radio, a Kenwood TS-2000 a normally reliable radio. We got him on a spare radio one of the other guys had, at which point he started wondering about his antenna working correctly.

Considering that this particular antenna gets mediocre reviews on eHam, we erected a telescopic mast, and hung a dipole on it.

And I had some really weird "Reverse Desense" problems that I never could overcome, but I think I know what it might be. I swapped out my filters and preamps (the most likely culprits) with no effect, so I just stuck to FO-29 for the weekend.

I "only" made 22 contacts, about half of what I normally do.

And my Azimuth rotor "broke" (I think) on the ride home. It now freewheels when it should be very hard to turn by hand, so I have to look in to what happened there. I transported the mount, rotors, and antennas fully assembled, and I think I shook something a wee bit too hard on the ride back home.

And I forgot my camera, BOTH days!

Only the guys running the CW station got through the whole weekend without a single problem.

Must have been all the garlic they hung around their trailer......

Friday, June 21, 2013

OUCH! I Killed My Optima Deep Cycle Battery

OOOPS!

Well, it's 7 years old, and I got a LOT of use out of it. I'd been charging it every few months to keep it from getting sulfated, and I just realized I hadn't had it out to use, or charge, in about a year.

It *might* come back if I get a different charger that will whack it with high-current pulses, but in my experience, while it might come back, you'll never get anywhere near full capacity out of it.

Lesson learned (actually, lesson remembered): CHARGE the damn thing on a regular basis!

I'll put it in the car, and exchange it for a new one on the way home from setting things up today.

Well, it's 7 years old, and I got a LOT of use out of it. I'd been charging it every few months to keep it from getting sulfated, and I just realized I hadn't had it out to use, or charge, in about a year.

It *might* come back if I get a different charger that will whack it with high-current pulses, but in my experience, while it might come back, you'll never get anywhere near full capacity out of it.

Lesson learned (actually, lesson remembered): CHARGE the damn thing on a regular basis!

I'll put it in the car, and exchange it for a new one on the way home from setting things up today.

Tuesday, June 18, 2013

Ready for Field Day

Made a bunch of satellite contacts over on Sunday, confirming things work As Advertised.

I pick up a little 5 x 7 trailer from U-Haul on Thursday, load it up Friday with my son, and head down to the site for setup.

More info on Field Day, and all things Amateur Radio, at the ARRL website.

.

.

I pick up a little 5 x 7 trailer from U-Haul on Thursday, load it up Friday with my son, and head down to the site for setup.

More info on Field Day, and all things Amateur Radio, at the ARRL website.

.

.

Saturday, June 15, 2013

Happy Father's Day!

To all my fellow Dads out there!

My Dad passed away in 1992, and I never realized how much I loved him until he was gone. But then I think it's that way with a lot of Father's and sons. We never appreciate all they did for us, and all the things they taught us. It's that old "Two Males Bumping Heads" thing.

I'm blessed I have a better relationship with my son than my Dad did with me. My Dad was pretty "Old School", and we used to disagree on some things that I thought were important. I know now that he just didn't understand why I did some of the things I did, and I didn't understand that he didn't understand.

Some of my "projects", the race cars in particular, he was vehemently against. He always said that if I wanted to be a "grease monkey", I should join the Army and "Learn to do it right!".

To this day I don't know if that was a slam against the Army, or me......Dad was a SeaBee in WWII, and truly loved the Navy.

He didn't understand that I looked at it like an Engineering Project, to build the best car I could, using my 'different' way of looking at things than most other car builders did.

He finally got a glimmer when he stopped in to visit with the machinist that was doing all my work. He knew the machinist's Dad from the navy, and had sold my guy his Bridgeport mill and Logan lathe.

My machinist showed him the work he was doing for me, all my detailed notes and drawings for the parts I was having fabricated, and told my Dad that my concepts were some of the most innovative he'd ever seen, and Dad should be proud of me for being able to think like that, and having the ability to put it on paper, proper drawings and all.

After that, Dad kinda quit bugging me about the car, and when I started setting records, I heard from friends that he was baffled about why I was doing it, but proud of the good job I was doing.

So, in honor of Dad's everywhere, here's an old post I did sometime back.

My Dad passed away in 1992, and I never realized how much I loved him until he was gone. But then I think it's that way with a lot of Father's and sons. We never appreciate all they did for us, and all the things they taught us. It's that old "Two Males Bumping Heads" thing.

I'm blessed I have a better relationship with my son than my Dad did with me. My Dad was pretty "Old School", and we used to disagree on some things that I thought were important. I know now that he just didn't understand why I did some of the things I did, and I didn't understand that he didn't understand.

Some of my "projects", the race cars in particular, he was vehemently against. He always said that if I wanted to be a "grease monkey", I should join the Army and "Learn to do it right!".

To this day I don't know if that was a slam against the Army, or me......Dad was a SeaBee in WWII, and truly loved the Navy.

He didn't understand that I looked at it like an Engineering Project, to build the best car I could, using my 'different' way of looking at things than most other car builders did.

He finally got a glimmer when he stopped in to visit with the machinist that was doing all my work. He knew the machinist's Dad from the navy, and had sold my guy his Bridgeport mill and Logan lathe.

My machinist showed him the work he was doing for me, all my detailed notes and drawings for the parts I was having fabricated, and told my Dad that my concepts were some of the most innovative he'd ever seen, and Dad should be proud of me for being able to think like that, and having the ability to put it on paper, proper drawings and all.

After that, Dad kinda quit bugging me about the car, and when I started setting records, I heard from friends that he was baffled about why I was doing it, but proud of the good job I was doing.

So, in honor of Dad's everywhere, here's an old post I did sometime back.

Things My Father

Taught Me

Any job worth doing is worth doing well, or don't do it at all.

If you don't know, ASK!

If you think you know, but aren't sure, find an expert and ASK!

(My Dad really did believe the “No Such Thing As A Dumb Question”

mantra).

LEARN the proper, correct names of your tools, whether a hand tool or

a machine tool.

Make a drawing or sketch and materials list before you start.

Have all the required tools and materials on hand before starting.

Do your layout work on the side that won't be seen, and protect the

finish side during cutting and machining.

Measure TWICE, cut ONCE!

Remove all jewelry and loose clothing before using machine tools.

Roll your sleeves up, and tie back long hair.

Buy the best tools you can afford. The “pain” of paying for

quality tools only lasts a little while, while the pain of using

cheap tools lasts much longer, and costs much more in damaged

projects and scrap.

Always clean your tools and work area when you're done for the day.

Store your tools properly.

Promptly clean any liquid spilled on the floor, and keep the floor

swept clean of any chips.

If using someone else's tools or work area, leave them/it cleaner

than when you started.

Keep your cutting tools sharp. Don't let them bang around in your

tool box. Dull tools can damage your work and cause accidents.

Keep your measuring tools clean and in a separate drawer. Precision

tools should be treated as such, and not allowed to bang around in a

drawer with other tools.

NEVER force a tool to do a job it wasn't designed for!

NEVER “store” the chuck key for your drill press in the chuck!

Always clamp the work to the table, or use a drilling vise to hold

it. Thin metal will “bite” when the bit breaks through the other

side, and a spinning workpiece can be extremely dangerous.

When possible, 'back up' your workpiece with a wood block or sheet so

that you don't drill into the table.

NEVER use your hands to remove the swarf or chips! Besides being very

sharp, they can also be very hot. Use a small brush to remove them.

Know the “Speeds and Feeds” for the material you're working with.

Aluminum is very different than steel.

Use the proper coolant/lubricant when required.

NEVER grind plastic, aluminum, copper, or “soft” brass on a

grinding wheel!

Keep your grinding wheels dressed and true, and stand off to the side

when turning on the grinder.

(Always good advice. I've had grinding wheels fly apart a second or

two after I turned the grinder on, and wire-wheels shed all their

wire!)

Unless you have no choice, or no other tool, use a WRENCH on a bolt

or nut, not a pair of pliers.

There are at least four types of 'cross-point' screw heads, and

they're NOT all “Phillips heads”.

(In case you're interested, there's Phillips, Fearson, JIS B 1012,

Pozidriv, Supadriv, Torq-set, and a couple of others that I forget.

The driver tips or bits are NOT interchangeable among them, as

they'll either chew up the screw, the bit, or both!)

There's no such thing as a “Flat Head Screwdriver”. There are

flat BLADE screwdrivers, but a “Flat Head” is a type of head on a

screw, not the tool to turn it.

A Pipe Wrench is NOT a Monkey Wrench.

The teeth on a hacksaw blade point FORWARDS when it's properly

installed.

Hacksaws and files cut on the FORWARD stroke ONLY. Lift them off the

work on the back stroke.

It's a poor workman who blames his tools.

Thursday, June 13, 2013

Rotators and Tracking Interface Calibrated and Verified

Since this is a completely new (NOTE: Used parts involved!) tracking antenna system, I had to verify it would actually track one of the satellites I'll be using for Field Day.

The system consists of a laptop running satellite tracking software, in my case SatPC32, which can dsiplay either a "flat" map:

or a "3D" map of whatever satellite(s) you're tracking:

The tracking program does much more than just display the relative positions of the satellites in relation to a ground observer. It also sends Doppler corrections to the radio, and position commands to the rotator interface.

I'll explain the Doppler Shift corrections first.

We've all experienced Doppler Shift before. I'm sure you've heard of the example where when a train (or car) is coming at you blowing the horn. As the train approaches, and then passes you, you hear distinct shift in the pitch of the tone. As the train is approaching, the sound waves are effectively "squeezed" together, shortening the time between them, and making the pitch (frequency) appear higher.

As the train moves away from you, the sound waves are "stretched" out, making the pitch (frequency) appear to be lower.

The ONLY time you'll hear the pitch the same as the train operator does, is when the relative velocity between you is ZERO.

The same thing happens with radio waves. As the satellite approaches, you have to tune the radio higher in frequency to clearly hear (no "voice shifting") the other people using the satellite, and as it departs away from you, you have to tune the radio lower in frequency.

Since we know the velocity of the satellite, and the velocity that we're moving along on the Earth, it's a simple ( you're kidding, right? ) matter to compute how much correction should be applied. The radio is connected to the laptop with a USB-to-Serial converter (the radio only has a serial port; the laptop only has USB ports), and the tracking program reads the radio's frequency, computes the required correction, and sends a command to the radio to tune to the new frequency.

In Ye Olde Daze of satellite operation, we all followed "The One True Rule for Doppler Tuning", and left the lower of the two frequencies alone, and tuned the higher of the two to make the correction.

What? TWO frequencies? Yep, satellite operation (at least on the Linear Transponder satellites) is "Full Duplex", like a telephone, meaning you can listen and talk at the same time. It's a bit weird at first to hear your own voice, delayed a small amount because of the round-trip distance between you and the satellite, but you quickly get used to it.

They way this is done, is to transmit on one of the VHF/UHF bands, and listen on the other, and this is not something your garden variety dual-band radio can do. Currently, there are only two multi-mode (FM, CW, and SSB) radios for sale that can operate on the Linear Transponder satellite, the Kenwood TS-2000 and the Icom IC-9100. There's a wide variety of used radios that work, like my Yaesu FT-847, along with other Yaesu, Kenwood, and Icom radios, but many people are wary of buying used radios.

I'll verify the radio operates correctly tomorrow, but since I've used this radio, this laptop, and this tracking program more than a few times, I'm confident it will work fine,

The other important thing the tracking software can do is send commands to an interface unit to steer the antennas, and that's what I tested tonight.

The control box for the antenna positioners (a.k.a. "rotators" or "rotors") I use has a connector on the back to allow an interface unit to plug in to it, and "translate" commands from the tracking program into antenna movement.

The rotors themselves are pretty simple. They use a small motor and gear train to develop the torque required to move the antenna, and have a potentiometer mechanically linked to the output shaft that develops a voltage proportional to the position of the output shaft.

0* gives 0 Volts, and 360* gives 5 Volts on the Azimuth rotor, and the Elevation rotor gives 0 Volts at 0*, and 5 Volts at 180*.

The purpose of the interface box is to measure and record these voltages, and then move the antennas in response to the data generated by the tracking program.

For this new setup, I'm using an "LVB Tracker" that I bought several years ago, but hadn't used until tonight:

During the calibration procedure, you run the rotors to their zero position, store the digitized voltage value in EEPROM, and then run them to "Full Scale", and do the same. The controller now "knows" what voltage corresponds to what position the antennas are pointing. If the tracking program data says that the satellite is currently at due South (180* Azimuth), and 45* above the horizon, it simply moves the rotors until the voltage from the potentiometers match the stored values for that position, and stops. Every 5 seconds it updates the antenna position if required, and then "sleeps" again.

So, after I calibrated the rotors and interface box, I waited for the next satellite to come over the horizon to see if it all worked.

Sure enough, when AO-7 was at -1 degree, the tracking program made a voice announcement, and the antennas begin to move from their parked position to where the satellite would be popping up. Watching the laptop screen, and the antennas, confirmed that yep, it was tracking the satellite as expected, and one more thing got crossed off the list.

When I get home from work Friday, I'll connect the coax to the antennas, connect the power leads to the preamps, set up the radio and laptop, and try and make a few contacts.

And Sunday will be "Radio Play Day", just to confirm it all works for more than a few minutes!

.

.

.

The system consists of a laptop running satellite tracking software, in my case SatPC32, which can dsiplay either a "flat" map:

or a "3D" map of whatever satellite(s) you're tracking:

The tracking program does much more than just display the relative positions of the satellites in relation to a ground observer. It also sends Doppler corrections to the radio, and position commands to the rotator interface.

I'll explain the Doppler Shift corrections first.

We've all experienced Doppler Shift before. I'm sure you've heard of the example where when a train (or car) is coming at you blowing the horn. As the train approaches, and then passes you, you hear distinct shift in the pitch of the tone. As the train is approaching, the sound waves are effectively "squeezed" together, shortening the time between them, and making the pitch (frequency) appear higher.

As the train moves away from you, the sound waves are "stretched" out, making the pitch (frequency) appear to be lower.

The ONLY time you'll hear the pitch the same as the train operator does, is when the relative velocity between you is ZERO.

The same thing happens with radio waves. As the satellite approaches, you have to tune the radio higher in frequency to clearly hear (no "voice shifting") the other people using the satellite, and as it departs away from you, you have to tune the radio lower in frequency.

Since we know the velocity of the satellite, and the velocity that we're moving along on the Earth, it's a simple ( you're kidding, right? ) matter to compute how much correction should be applied. The radio is connected to the laptop with a USB-to-Serial converter (the radio only has a serial port; the laptop only has USB ports), and the tracking program reads the radio's frequency, computes the required correction, and sends a command to the radio to tune to the new frequency.

In Ye Olde Daze of satellite operation, we all followed "The One True Rule for Doppler Tuning", and left the lower of the two frequencies alone, and tuned the higher of the two to make the correction.

What? TWO frequencies? Yep, satellite operation (at least on the Linear Transponder satellites) is "Full Duplex", like a telephone, meaning you can listen and talk at the same time. It's a bit weird at first to hear your own voice, delayed a small amount because of the round-trip distance between you and the satellite, but you quickly get used to it.

They way this is done, is to transmit on one of the VHF/UHF bands, and listen on the other, and this is not something your garden variety dual-band radio can do. Currently, there are only two multi-mode (FM, CW, and SSB) radios for sale that can operate on the Linear Transponder satellite, the Kenwood TS-2000 and the Icom IC-9100. There's a wide variety of used radios that work, like my Yaesu FT-847, along with other Yaesu, Kenwood, and Icom radios, but many people are wary of buying used radios.

I'll verify the radio operates correctly tomorrow, but since I've used this radio, this laptop, and this tracking program more than a few times, I'm confident it will work fine,

The other important thing the tracking software can do is send commands to an interface unit to steer the antennas, and that's what I tested tonight.

The control box for the antenna positioners (a.k.a. "rotators" or "rotors") I use has a connector on the back to allow an interface unit to plug in to it, and "translate" commands from the tracking program into antenna movement.

The rotors themselves are pretty simple. They use a small motor and gear train to develop the torque required to move the antenna, and have a potentiometer mechanically linked to the output shaft that develops a voltage proportional to the position of the output shaft.

0* gives 0 Volts, and 360* gives 5 Volts on the Azimuth rotor, and the Elevation rotor gives 0 Volts at 0*, and 5 Volts at 180*.

The purpose of the interface box is to measure and record these voltages, and then move the antennas in response to the data generated by the tracking program.

For this new setup, I'm using an "LVB Tracker" that I bought several years ago, but hadn't used until tonight:

During the calibration procedure, you run the rotors to their zero position, store the digitized voltage value in EEPROM, and then run them to "Full Scale", and do the same. The controller now "knows" what voltage corresponds to what position the antennas are pointing. If the tracking program data says that the satellite is currently at due South (180* Azimuth), and 45* above the horizon, it simply moves the rotors until the voltage from the potentiometers match the stored values for that position, and stops. Every 5 seconds it updates the antenna position if required, and then "sleeps" again.

So, after I calibrated the rotors and interface box, I waited for the next satellite to come over the horizon to see if it all worked.

Sure enough, when AO-7 was at -1 degree, the tracking program made a voice announcement, and the antennas begin to move from their parked position to where the satellite would be popping up. Watching the laptop screen, and the antennas, confirmed that yep, it was tracking the satellite as expected, and one more thing got crossed off the list.

When I get home from work Friday, I'll connect the coax to the antennas, connect the power leads to the preamps, set up the radio and laptop, and try and make a few contacts.

And Sunday will be "Radio Play Day", just to confirm it all works for more than a few minutes!

.

.

.

Tuesday, June 11, 2013

Field Day Satellite Antenna System Up And Running

And had more than enough daylight to put the tools away, and clean up!

This iteration of my portable setup is WAY easier to put together, align to North, and calibrate.

I was able to tip it over and rest it on a "saw horse", and get the cross-boom with antenna through the Elevation rotor, get the clamps on, and get it tightened down, all by myself.

Doing this with the 9' tower took two people, and they had to know what they were doing.

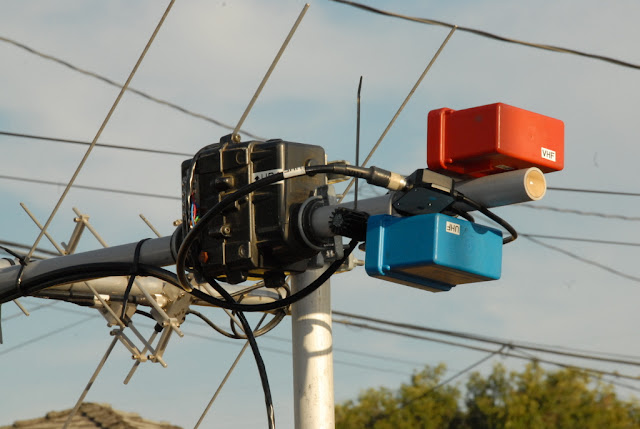

And with the short cross-boom, both the preamps (red and blue boxes) and the diplexer (little thing between the preamps) get mounted on the far side of the Elevation rotator, allowing a nice cable path from the antenna.

So, after I got the top end assembled, I tipped the tower/antenna up, and walked if over to where it clears all the overhead power/fiber/phone/cableTV wires.

And then I ran the rotators full CW/CCW in Azimuth, and from 0* through 90* to 180* in Elevation.

No cable bind anywhere in the range of travel, which is always a good thing!

For now it's sitting at "North, 0*", and when I get home from work tomorrow I'll connect the coax and DC power up to the two preamps, drag out the radio, power supply, and rotator/laptop interface, and see how it all plays together.

This is a shot I took of the preamp end of the cross-boom. You can see the wood dowel in the grey fiberglass tube, and my somewhat sloppy job of "securing" the diplexer between the two preamps.

So another hour or two of connecting stuff up, and I'll be on the air.

.

.

.

This iteration of my portable setup is WAY easier to put together, align to North, and calibrate.

I was able to tip it over and rest it on a "saw horse", and get the cross-boom with antenna through the Elevation rotor, get the clamps on, and get it tightened down, all by myself.

Doing this with the 9' tower took two people, and they had to know what they were doing.

And with the short cross-boom, both the preamps (red and blue boxes) and the diplexer (little thing between the preamps) get mounted on the far side of the Elevation rotator, allowing a nice cable path from the antenna.

So, after I got the top end assembled, I tipped the tower/antenna up, and walked if over to where it clears all the overhead power/fiber/phone/cableTV wires.

And then I ran the rotators full CW/CCW in Azimuth, and from 0* through 90* to 180* in Elevation.

No cable bind anywhere in the range of travel, which is always a good thing!

For now it's sitting at "North, 0*", and when I get home from work tomorrow I'll connect the coax and DC power up to the two preamps, drag out the radio, power supply, and rotator/laptop interface, and see how it all plays together.

This is a shot I took of the preamp end of the cross-boom. You can see the wood dowel in the grey fiberglass tube, and my somewhat sloppy job of "securing" the diplexer between the two preamps.

So another hour or two of connecting stuff up, and I'll be on the air.

.

.

.

Monday, June 10, 2013

"Silk Pursing" for Field Day 2013

Well, since I'm feeling much better, I reversed my decision to not operate at Field Day this year, but I will be scaling things down a bit.

Rather than bringing the "big" tower, seen in the background, I've come up with this smaller, lighter, and easier to handle replacement.

It's based on a Rohn "Non Penetrating Roof Mount" leftover from when I ran my community wireless (WiFi) Hot Spot back at my bachelor pad. The rotator is about 5-1/2 feet off the ground, with another 24 inches of mast sticking out of the top. Up on top of the stub mast will go the elevation rotator:

The four studs sticking up out of the housing are part of a set of clamps Yaesu calls a "Separation Kit", which allows you to split the Azimuth and Elevation motors and mount them separately. The two halves of the clamp spread apart, then slip over the stub mast, and you tighten the bolts to clamp it down.

Through the elevation rotator will go a tubular fiberglass cross-boom with a wood dowel inside so you don't crush the tube when you tighten the clamps, and mounted on the cross-boom will be the "Dual Band Easy Satellite Antenna" I purchased several years ago from Gulf Alpha Antennas.

I'm calling this "Silk Pursing" because I'm making it up out of bits and pieces I've had laying around. The rotators and cross-boom were going to be used on my "New And Improved" portable satellite station I was building to use for the even on the Iowa a while back. That got canned because the "Heavy Duty" eBay tripod I bought wasn't, and I busted the legs on it. The antenna was bought for previous Field Day events, worked extremely well, and got stored in the rafters when I built the "big" tower, and the preamps I'll be using came from a couple of places.

Coax I have by the spool, and connectors by the box!

I should be able to get the rotors and antenna all put together in the next day or two, test them, calibrate the rotor position pots and see how well it plays with the control software, and possibly be On-The-Air with it Sunday.

Set up at the Field Day site is in 10 days, and the clock is ticking......

.

.

Rather than bringing the "big" tower, seen in the background, I've come up with this smaller, lighter, and easier to handle replacement.

It's based on a Rohn "Non Penetrating Roof Mount" leftover from when I ran my community wireless (WiFi) Hot Spot back at my bachelor pad. The rotator is about 5-1/2 feet off the ground, with another 24 inches of mast sticking out of the top. Up on top of the stub mast will go the elevation rotator:

The four studs sticking up out of the housing are part of a set of clamps Yaesu calls a "Separation Kit", which allows you to split the Azimuth and Elevation motors and mount them separately. The two halves of the clamp spread apart, then slip over the stub mast, and you tighten the bolts to clamp it down.

Through the elevation rotator will go a tubular fiberglass cross-boom with a wood dowel inside so you don't crush the tube when you tighten the clamps, and mounted on the cross-boom will be the "Dual Band Easy Satellite Antenna" I purchased several years ago from Gulf Alpha Antennas.

I'm calling this "Silk Pursing" because I'm making it up out of bits and pieces I've had laying around. The rotators and cross-boom were going to be used on my "New And Improved" portable satellite station I was building to use for the even on the Iowa a while back. That got canned because the "Heavy Duty" eBay tripod I bought wasn't, and I busted the legs on it. The antenna was bought for previous Field Day events, worked extremely well, and got stored in the rafters when I built the "big" tower, and the preamps I'll be using came from a couple of places.

Coax I have by the spool, and connectors by the box!

I should be able to get the rotors and antenna all put together in the next day or two, test them, calibrate the rotor position pots and see how well it plays with the control software, and possibly be On-The-Air with it Sunday.

Set up at the Field Day site is in 10 days, and the clock is ticking......

.

.

Thursday, June 6, 2013

"Gun Control" for Dummies

Massad Ayoob knocks one out of the park.

It's not about "guns", it's about "control".

But then you knew that already.....

.

.

It's not about "guns", it's about "control".

But then you knew that already.....

.

.

Vahevala by Loggins and Messina

One of my favorite songs from days long gone....

I'm thinking about when I was a sailor

Spent my time on the open seas

When we'd stay off the coast of Jamaica

I'd secretly steal ashore

The natives were waiting for

The boy with the lazy soul

To sing with the sailor

[Chorus:]

Vahevala, homeless sailor

Vahevala, homeward sail away

Vahevala, homeless sailor

Vahevala, homeward sail away

Every evening I'd be gone

Back on board by break of dawn

I'm thinking about the nights in Jamaica

Pretty girls dancin' here and there

Stole a keg and now I'm drunk as a sailor

The captain he don't know

Where Billy he done go

But I'm singing with native girls

The songs of a sailor

[Chorus]

Every night in Jamaica I'd sing with the lady

And drink with the men till the morning appear

Healthy sunshine is fresh on my face

As the songs of the night puts the ring in my ear

[Chorus]

.

.

I'm thinking about when I was a sailor

Spent my time on the open seas

When we'd stay off the coast of Jamaica

I'd secretly steal ashore

The natives were waiting for

The boy with the lazy soul

To sing with the sailor

[Chorus:]

Vahevala, homeless sailor

Vahevala, homeward sail away

Vahevala, homeless sailor

Vahevala, homeward sail away

Every evening I'd be gone

Back on board by break of dawn

I'm thinking about the nights in Jamaica

Pretty girls dancin' here and there

Stole a keg and now I'm drunk as a sailor

The captain he don't know

Where Billy he done go

But I'm singing with native girls

The songs of a sailor

[Chorus]

Every night in Jamaica I'd sing with the lady

And drink with the men till the morning appear

Healthy sunshine is fresh on my face

As the songs of the night puts the ring in my ear

[Chorus]

.

.

Tuesday, June 4, 2013

15 Minutes of Nuclear Explosions

Definitely not something you want to be near, but beautiful in a scary sort of way.

H/T to The Market-Ticker!

H/T to The Market-Ticker!

Sunday, June 2, 2013

Radio Weekend on the Battleship Iowa

As part of Museum Ships Weekend, one of the groups I'm with was able to secure permission to operate from the Comm Center aboard the Iowa this weekend.

I didn't operate the entire time my buddies were there as I'm still not 100%, but I put in about 4 hours Saturday, and 4 hours today.

We had a pretty good time, although Saturday was a bit uncomfortable, as the ship's HVAC system is non-functional at this time, and we had to rely on box fans in the hatches and passageways to blow some cool outside air into the spaces we were using. By 1400, we were all soaked with sweat, so I left early, came home, and took a nap.

Today was overcast and much cooler, so I was able to hang in there for over 5 hours, at which time we decided it probably wasn't going to be worthwhile operating until the end of the event, and shut down early.

We used pretty simple equipment, an Icom IC-718 compact HF transceiver, and LDG antenna "tuner", and the Discage antenna on the bow of the Iowa, and the "trussed whip" antenna located a bit further aft.

Here's an excellent article about the various antennas aboard an Iowa-class battleship, courtesy of one of our sister ships, the USS Missouri.

We had a nice 30 minute "rag chew" today the The Mighty Mo, marking the first time we contacted her from the Iowa.

BTW....all FOUR Iowa-class ships were on the air this weekend, marking another first. Next year will be the 60th anniversary of the first time all four steamed together, and we'll be working up a big event for that!

The discage is a rather unusual antenna, in that it can be fed two ways. If you feed it at the junction between the "disc" and the "cage", it acts as an HF Discone antenna, and will radiate efficiently from 10 MHz to 30 MHz.

If you feed the lower cage portion against ground, it acts as a wide band monopole, and works very well from 6 MHz to 10 MHz.

Discones are more commonly used at VHF and above, and you've probably seen one, and called it a "scanner antenna". They don't have ANY gain, so they're not much better than a piece of wire, BUT they are remarkably broadbanded, often operating over 10:1 frequency range, making them very popular with scanner users.

I don't know for sure how many total contacts we made, but I logged almost 200 during the two days, and operated the radio for at least that many more.

The Iowa is a marvelous place. Every time I walk down a passageway, go up or down a ladder, or just sit in one of the spaces, I get an eerie feeling, almost like I'm being watched. Some of the other people who volunteer feel the same thing, and it's a reminder to us that we're merely stewards of the ship, and are just keeping it clean and well kept for the real owners, namely all the people who served on her, and gave her life, during the time she was a Ship of the Line.

And I'm honored to be allowed to help keep her "shipshape"......

I didn't operate the entire time my buddies were there as I'm still not 100%, but I put in about 4 hours Saturday, and 4 hours today.

We had a pretty good time, although Saturday was a bit uncomfortable, as the ship's HVAC system is non-functional at this time, and we had to rely on box fans in the hatches and passageways to blow some cool outside air into the spaces we were using. By 1400, we were all soaked with sweat, so I left early, came home, and took a nap.

Today was overcast and much cooler, so I was able to hang in there for over 5 hours, at which time we decided it probably wasn't going to be worthwhile operating until the end of the event, and shut down early.

We used pretty simple equipment, an Icom IC-718 compact HF transceiver, and LDG antenna "tuner", and the Discage antenna on the bow of the Iowa, and the "trussed whip" antenna located a bit further aft.

Here's an excellent article about the various antennas aboard an Iowa-class battleship, courtesy of one of our sister ships, the USS Missouri.

We had a nice 30 minute "rag chew" today the The Mighty Mo, marking the first time we contacted her from the Iowa.

BTW....all FOUR Iowa-class ships were on the air this weekend, marking another first. Next year will be the 60th anniversary of the first time all four steamed together, and we'll be working up a big event for that!

The discage is a rather unusual antenna, in that it can be fed two ways. If you feed it at the junction between the "disc" and the "cage", it acts as an HF Discone antenna, and will radiate efficiently from 10 MHz to 30 MHz.

If you feed the lower cage portion against ground, it acts as a wide band monopole, and works very well from 6 MHz to 10 MHz.

Discones are more commonly used at VHF and above, and you've probably seen one, and called it a "scanner antenna". They don't have ANY gain, so they're not much better than a piece of wire, BUT they are remarkably broadbanded, often operating over 10:1 frequency range, making them very popular with scanner users.

I don't know for sure how many total contacts we made, but I logged almost 200 during the two days, and operated the radio for at least that many more.

The Iowa is a marvelous place. Every time I walk down a passageway, go up or down a ladder, or just sit in one of the spaces, I get an eerie feeling, almost like I'm being watched. Some of the other people who volunteer feel the same thing, and it's a reminder to us that we're merely stewards of the ship, and are just keeping it clean and well kept for the real owners, namely all the people who served on her, and gave her life, during the time she was a Ship of the Line.

And I'm honored to be allowed to help keep her "shipshape"......

Saturday, June 1, 2013

Don't Worry, I'm Doing Fine.....

I haven't posted on any of the blogs I regularly visit because I've been using my wife's PC.

And I'm too damn lazy to have to enter all that info on each blog I want to comment on.

Since The Kids moved out, she's been doing a major make-over on their room, and I pulled everything out of the middle bedroom I shared as a Radio Room/Weight Lift Room/Clothes Closet with her son and his girlfriend.

I helped her pull out all the plastic screw anchors, patch the holes, "Vee" out the cracks, and spackle the walls. She handled all the priming and painting, while I dragged *everything* left out of the middle bedroom.

Got some more IKEA crap so it would match the other IKEA crap I bought when I first moved in, and spent a couple of days moving little "scale model" pieces of paper around until I was happy with the new arrangement.

Then I put the "1:1 Scale" furniture in the room, and I'm slowly moving all the computer and radio stuff back in.

I'll have about three times the room I had before, and _might_ be able to move the "Electronics Repair Area" out of the breakfast nook in the kitchen, and into the new "Lab Area" along one wall of the room.

Still taking it easy, and I've been cleared to return to work on June 10.

And I'm too damn lazy to have to enter all that info on each blog I want to comment on.

Since The Kids moved out, she's been doing a major make-over on their room, and I pulled everything out of the middle bedroom I shared as a Radio Room/Weight Lift Room/Clothes Closet with her son and his girlfriend.

I helped her pull out all the plastic screw anchors, patch the holes, "Vee" out the cracks, and spackle the walls. She handled all the priming and painting, while I dragged *everything* left out of the middle bedroom.

Got some more IKEA crap so it would match the other IKEA crap I bought when I first moved in, and spent a couple of days moving little "scale model" pieces of paper around until I was happy with the new arrangement.

Then I put the "1:1 Scale" furniture in the room, and I'm slowly moving all the computer and radio stuff back in.

I'll have about three times the room I had before, and _might_ be able to move the "Electronics Repair Area" out of the breakfast nook in the kitchen, and into the new "Lab Area" along one wall of the room.

Still taking it easy, and I've been cleared to return to work on June 10.

Subscribe to:

Comments (Atom)

RAIN!

Glorious RAIN! Along with about 3" of snow that melted as soon as it hit the streets and sidewalks. Total precip as measured by my rai...

-

FOURTH time I've written this post. MY Muse has apparently vacated the premises, leaving me too busy doing other things to keep both m...

-

With apologies to The Control Voice.... Yup.....got The Busies the last few weeks. Lots of stuff happening this week, including my Nuclea...